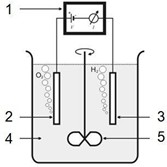

1 = Rectifier

2 = Anode: the positive pole of the rectifier.

This will be the stainless steel component

3 = Cathode: the negative pole of the rectifier.

This is made of copper (Cu).

4 = Electrolyte (phosphoric acid H3PO4 + sulphuric acid H2SO4 + additives) at approximately 50ºC

5 = Agitator (stirrer).

Setup for austenitic steel electropolishing (Source: EHEDG Doc.18)

RIGHTER electro-polishing of stainless steel items is compliant to ASME BPE requirements

The high surface quality is the result of years of experiences and know-how in processing electro-polishing. Significant process parameters are observed :

- Operating temperature of the electrolyte solution.

- The amplitude of the cathodes and their location relevant to the product.

- ph value of the solution.

- Processing duration that the part is immersed in the solution.

As a result, RIGHTER products stand out from competing products in the following ways:

A thicker EP layer to minimize rouging

Higher Chrome concentration for better corrosion resistance

Guaranteed smoothness (Ra) in all internal surfaces to reduce Bio film

US 13040

US 13040  GB 10067

GB 10067  CA 9139

CA 9139  AU 9123

AU 9123  IE 6043

IE 6043  NZ 3255

NZ 3255  BR 1967

BR 1967  CN 823

CN 823