HK-KT Series

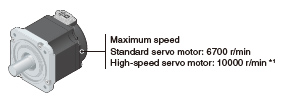

Servo motors with a 26-bit batteryless absolute position encoderRated speed: 3000 r/min *1Maximum speed: 6700 r/min *1Our product line includes 400 V and flat type models.The servo motors have an all-in-one connector, making the connection simple.

Small capacity, ultra-low inertia

HK-MT Series

Servo motors with a 26-bit batteryless absolute position encoderRated speed: 3000 r/minMaximum speed: 10000 r/min (available with the high-speed type models *2)The servo motors have an all-in-one connector, making the connection simple.

Medium capacitu, medium inertia

HK-ST Series

Servo motors with a 26-bit batteryless absolute position encoderRated speed: 2000 r/min, 3000 r/minTwo types of rated speed are available.The cables for the encoder, the electromagnetic brakes, and the power are equipped with one-touch lock.

Medium capacity, ultra-low inertia

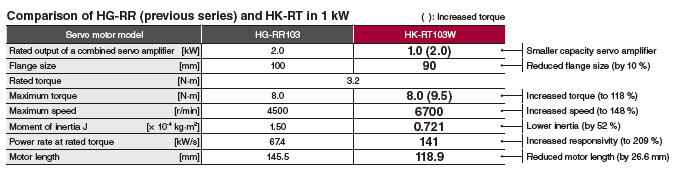

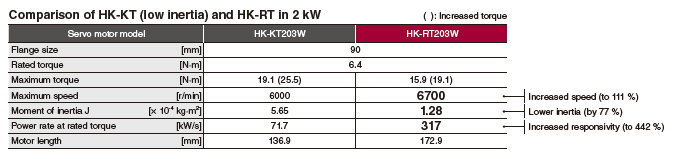

HK-RT Series

Servo motors with a 26-bit batteryless absolute position encoderRated speed: 3000 r/minMaximum speed: 6700 r/min *1Our product line includes 400 V and flat type models.The servo motors (1 to 2 kW) have an all-in-one connector, making the connection simple.

Specifications:

A. Batteryless Absolute Position Encoder as Standard

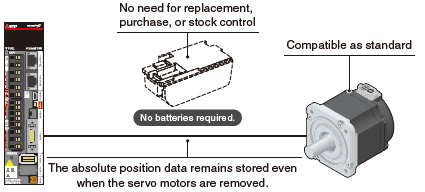

1. Eliminate the Need for Purchase/Replacement/Stock Control

Servo motors come equipped with a batteryless absolute position encoder as standard, making it possible to configure absolute position systems without the use of batteries or any other options.Moreover, maintenance costs are reduced as a result of eliminating the battery replacement and stock control.

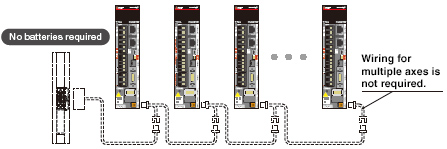

2. Reduce Wiring for Multi-Axis Systems

In a conventional multi-axis system, battery cables are necessary between the servo amplifiers. Now that the batteries are not required with the use of the batteryless absolute position encoders, wiring battery cables for multi-axis systems is not required.

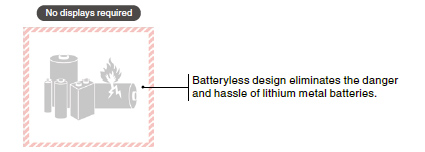

3. Save Time in Transporting

Position data remains stored even when the rotary servo motors are disconnected from the servo amplifiers. Thus, control cabinets can be separated from the machines without losing the position data, making it easy to transport machines for use at a new location.The encoder does not require lithium metal batteries, allowing machines to be transported by air or sea without special handling.

B. Single Connector/One-Touch Lock/Single Cable Type

1. Single Connector/Single Cable Type/One-Touch Lock

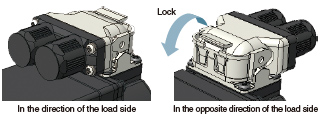

The single connector for the HK-KT/HK-MT/HK-RT *1 series combines the motor power supply, encoder, and electromagnetic brake into a single cable. The one-touch lock eliminates the need for tightening screws, making wiring easy. The servo motors are also compatible with the dual cable type. The cables can be mounted either horizontally or vertically according to your selection.Refer to "MELSERVO-J5 catalog" for details of servo motor cable

- Horizontally mounted single cable type with one-touch lock

- Horizontally mounted dual cable type with one-touch lock

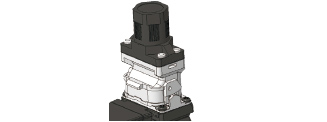

- Vertically mounted single cable type with one-touch lock

- Vertically mounted dual cable type with one-touch lock

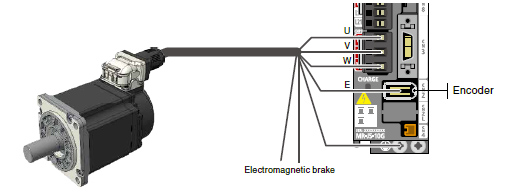

- Connection example of one-touch lock with single cable type

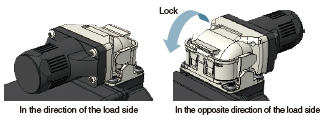

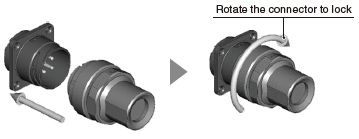

2. One-Touch Lock

HK-ST/HK-RT *1 series servo motors boast a greatly simplified installation process through use of the onetouch lock system. The one-touch lock can be used to mount connectors for the motor power supply, encoder, and electromagnetic brake, which eliminates the need for tightening screws. The servo motors are compatible with both straight and angle type connectors and also supports traditional screw-tightened connectors.

C. Expanding Combinations of Servo Amplifiers and Servo Motors

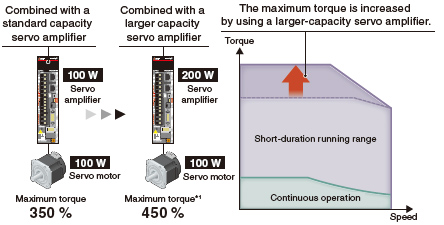

1. Increases Maximum Torque by Combining with Larger-Capacity Servo Amplifiers

It is possible to increase the maximum torque and achieve a shorter cycle time by combining the servo motor with a larger-capacity servo amplifier.

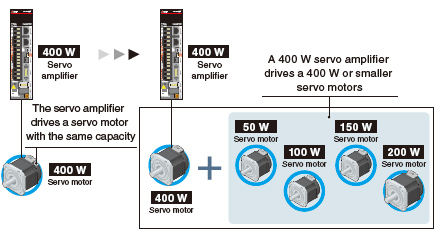

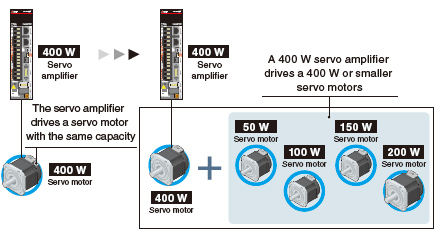

2. Drives Smaller Capacity Servo Motors

Servo amplifiers are able to drive servo motors with a smaller capacity than the servo amplifier being used, reducing the kinds of spare parts that are needed. For example, 400 W servo amplifiers are compatible with the following servo motors: 50 W, 100 W, 150 W, 200 W, and 400 W models. It is possible to increase the maximum torque and achieve a shorter cycle time by combining the servo motor with a larger-capacity servo amplifier.

Servo amplifiers are able to drive servo motors with a smaller capacity than the servo amplifier being used, reducing the kinds of spare parts that are needed. For example, 400 W servo amplifiers are compatible with the following servo motors: 50 W, 100 W, 150 W, 200 W, and 400 W models. It is possible to increase the maximum torque and achieve a shorter cycle time by combining the servo motor with a larger-capacity servo amplifier.

3. Drives Smaller Capacity Servo Motors

Servo amplifiers are able to drive servo motors with a smaller capacity than the servo amplifier being used, reducing the kinds of spare parts that are needed. For example, 400 W servo amplifiers are compatible with the following servo motors: 50 W, 100 W, 150 W, 200 W, and 400 W models.

Servo amplifiers are able to drive servo motors with a smaller capacity than the servo amplifier being used, reducing the kinds of spare parts that are needed. For example, 400 W servo amplifiers are compatible with the following servo motors: 50 W, 100 W, 150 W, 200 W, and 400 W models.

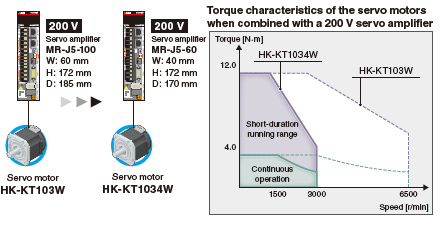

4. Drives 200 V/400 V Class Servo Motors

The 200 V servo amplifiers can drive both 200 V and 400 V servo motors, and the 400 V servo motors may produce torque that is sufficient for operation when combined with smaller-capacity 200 V servo amplifiers.Lowering of the capacity of the servo amplifier contributes to lower costs and reduced installation space.

The 200 V servo amplifiers can drive both 200 V and 400 V servo motors, and the 400 V servo motors may produce torque that is sufficient for operation when combined with smaller-capacity 200 V servo amplifiers.Lowering of the capacity of the servo amplifier contributes to lower costs and reduced installation space.

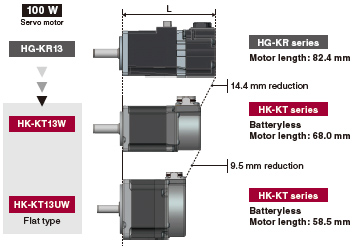

D. Compact Servo Motors with a Batteryless Absolute Position Encoder

HK-KT series servo motors come equipped with a batteryless absolute position encoder and are more compact than the previous generation HG-KR series.Flat types are also available in the HK-KT product line, contributing to a compact machine design.

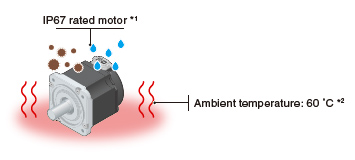

E. Improved Environmental Resistance

Servo motors feature enhanced environmental resistance.Ingress protection (IP) rating of the servo motors: IP67 *1Designed for an ambient temperature of up to 60 ��. *2

- 1. If the IP rating of the servo motor differs from those of option cables and connectors, overall IP rating depends on the lowest of all.

- 2. Derate the speed/torque when using the servo motors at high ambient temperatures.

1. Compact, High-Power Rate Servo Motors for High-Speed Operation

2. Maximum Speed of 10000 r/min

The high-power rate servo motors are optimal for packaging machines and material handling systems.Servo motors with maximum speed of 10000 r/min *1 are added to the product lines, contributing to a shorter cycle time.

G. HK-ST Servo Motors with Rated Speed of 3000 r/min

- HK-ST series (medium capacity, medium inertia) releases servo motors with rated speed of 3000 r/min.Conventional HG-JR servo motors can be replaced with HK-ST series and HK-KT series (small capacity, low inertia) to which new models such as HK-KT63UW are added.(Motor flange size [mm]: 90 × 90 and 130 × 130)

US 15106

US 15106  GB 11844

GB 11844  CA 10037

CA 10037  AU 9612

AU 9612  IE 5041

IE 5041  NZ 4529

NZ 4529  BR 2179

BR 2179  SG 1101

SG 1101