The Yokogawa CW500 is a portable power meter that utilizes current clamp-on probes, easy to use navigation screens and bluetooth and SD cards for communication and data logging. These features enable user-friendly power consumption and power quality measurements in the field that conform to IEC61000-4-30 Class S. This standard dictates that two measuring instruments of similar rating must measure within some percentage of each other when exposed to the same signal.

Brochures

- CW500 Power Quality Analyzer (3.7 MB)

- Process Test Tools Selection Guide (2.0 MB)

Utilities and substations contain large arrays of transformers, generators and electrical distribution networks. To maintain the health and safety of such infrastucture, a reliable power quality analyzer is needed. This power quality analyzer should be capable of not only logging single to multi-phase power, but also trend and monitor anomalies in the power system such as voltage sags,swells and dips, as well as flicker, inrush current, and demand changes. The CW500 power quality monitor is perfectly suited for this task due to its:

Varied Functionality

- Log anything from single phase two wire to three phase four wire systems, and everything in between

- Capture irregularities in your power system such as voltage sags,dips, swells and log them conviently to RAM or an SD card

- Log upto 50th orders of harmonics

- Vector display for convenient tracking of voltage/current phase relationships

Portability

- Small form factor and battery inputs allow the user to take this unit anywhere, anytime

- Use the free CW500 viewer to connect remotely to the unit to log data or view events in real-time

Ease of use

- Quickly and easily shift between setting up the unit or viewing logged variables and waveforms

- Supports USB and bluetooth

- Set a predetermined record length or schedule or a start time and duration for logging data

Key Features

- Power Measurement and Logging

- Power Quality Measurement

- User Support

- Analysis of Data and Report Generation

Power Measuring and Logging

- Simultaneously measures 3 CH Voltage input, 4 CH current clamp probe input, 2 CH DCV input.

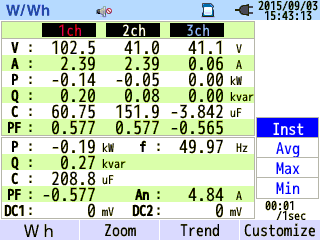

- Instantaneous/Average/Maximum/Minimum value list or trend graph screen of Voltage/ Current/Power/Power factor/Phase Angle/Phase Advanced Capacitance Calculation.

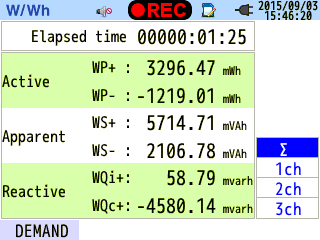

- Integration Value of Active/ Reactive/Apparent Energy is each displayed consumption and generation.

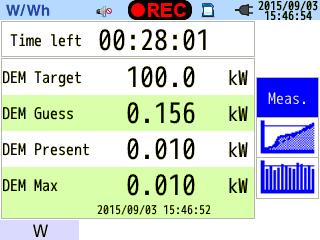

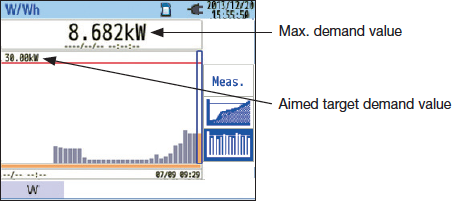

- Demand monitoring which displays screens of present power consumption compared to aimed demand power values.

User Support

Quick Start Guide Function:

- The Quick Start Guide Function supports correct wiring and setting before measuring.

- The Quick Start Guide Function automatically recognizes the type of current clamp probe.

Vector Display:

- The Vector Display indicates Voltage and Current phase difference and values between input channels of voltage and current.

- The Vector Display checks whether the wiring is correct or not.

Power Quality Measuring

Measure Temporary Malfunctions of the Power Line

- The CW500 captures temporary malfunction phenomena of the power line that can cause malfunction or destruction of devices due to voltage swell, voltage dip, interruption, transient voltage over, and inrush current by using a high sampling rate of 24 µs and RUS calculation.

- Event data contains the type of malfunction, occurred time or occurrence finish time, measured value and waveform of voltage and current of all channels for approx. 200 ms period.

- This measurement method conforms to IEC standard 61000- 4-30 Class S

Measure Continuous Malfunction of the Power Line

Harmonics

- Measure and display graphs and lists of up to the 50th Harmonic components of voltage, current, and power for each phase and total.

Flicker

- Measures 1-minute flicker (Pst, 1 min), short flicker, (Pst) and long flicker (Plt).

Unbalance rate

- Displays voltage and current unbalance rate on 3 phase wiring.

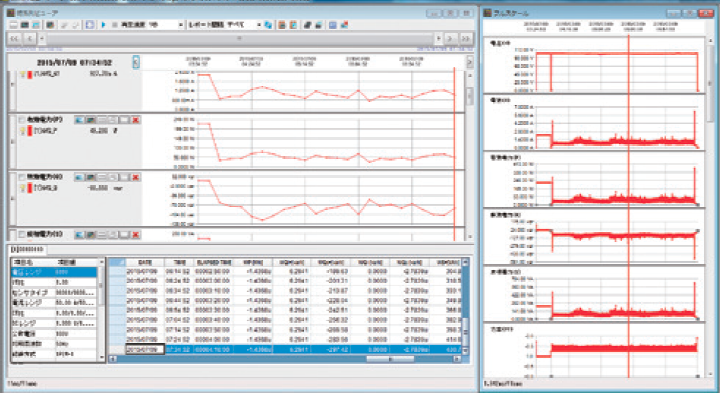

CW500Viewer (Included PC software)

- Automatically display the graphical and report data by clicking on the file on the PC display.

- Manage multiple settings of the unit.

- Measure in real-time using USB communication.

Types of data

- Integrated power data, power quality event data, main unit setting data, and screen capture data.

Memory card and interface

- SD memory card, USB communication, Bluetooth communication (available for US, Canada and Japan only).

Power Measuring

Power line and Input Channel: 3 CH Voltage, 4 CH for Current Clamp Probe.

1P2W (up to 4 systems), 1P3W (up to 2 systems), 3P3W2current (up to 2 systems), 3P3W3current, 3P4W

Power measuring item:

Instantaneous, average, maximum, and minimum values for each setting period:

Voltage/Current/Power (Active, Reactive, Apparent)/Power Factor/ Phase Angle/Frequency/Calculated Phase Shift Capacitance/DC voltage value 2 CH.

Integration Value

Energy (active, reactive, apparent), Demand (list or graph display of change in a specific period and as a whole)

Recording Interval Period

1/2/5/10/15/20/30 second, 1/2/5/10/15/20/30 minute, 1 hour/2 hours

Recording method

Manual, time, period

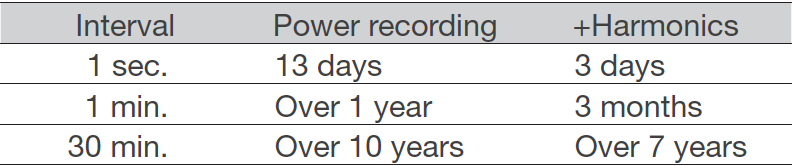

Estimated Recording Length with 2 GB SD card

- The recording length shortens according to the number of power quality events.

- Only the included SD memory card or dedicated SD memory card is guaranteed.

Various Measuring Screen

List display, zoom display by 4 or 8 divisions, trend graph display, integration value display for energy, demand list display of value, demand graph display for change of period, demand graph display for whole recording

List Display

Hems of measuring values can be selected with position.

Zoom Display

Zoom display can be selected by 4 or 8 divisions.

Trend Graph

Trend graph of voltage/ current/power/power factor/frequency/ advanced phase condenser external DC voltage.

Energy Display

List of active, apparent, reactive by consumption or generation.

Demand measuring

Demand is the average power value of a specific period (usually 30 minutes). The contract with the power supplier conditionally concerns the maximum average power value between a period for the consumption fee. This function supports how to maintain within the target consumption by monitoring the estimated demand value to the setting rate with the maximum demand value.

List of Demand Value

Graph display of change on specific period

Graph display of whole demand trend

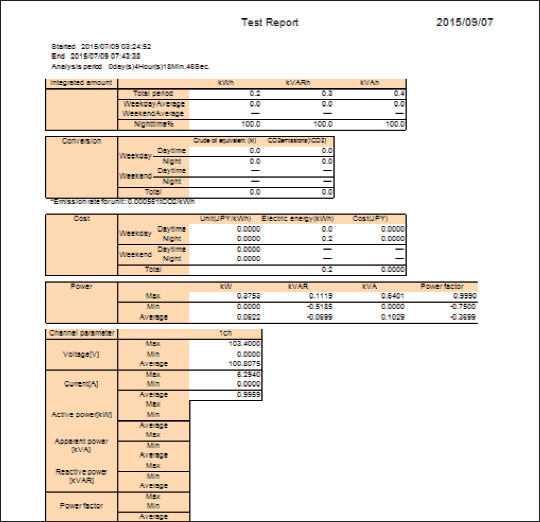

Analysis and Reporting of recorded data

Trend analysis graph

Sample of report

Power Quality Function

Short period power line malfunctions such as voltage swells, dips, interruptions, transients, over or inrush currents, or long periods of harmonic distortion/flicker may damage or reset your devices.

The CW500 helps to identify each of those short period malfunctions by recording occurrence time, occurrence finish time and waveforms. Additionally there is a digital output on occurrence.

Long period malfunctions can be analyzed by harmonics, flicker, waveform, or by checking on the unbalance rate calculation for a 3 phase measurement.

All data can be finalized into a report format with the included software. The CW500 conforms to the IEC standard of 61000-4-30 Class S.

User Support Function

User Friendly

Quick start guide and automatic type of clamp recognition

The quick start guide will show on-start measuring and how to wire and set the range before measuring. The automatic clamp detection will insure the settings are correct.

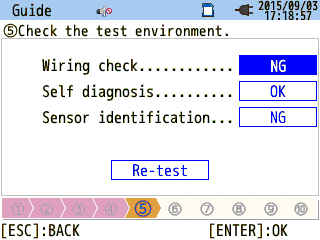

Start of guidance

PUSH the “START/STOP” key.

Select “Quick start guide”.

Select recording item.

Wiring

Select the wiring and the appropriate connection diagram will be displayed.

Connect accordingly.

Wiring check/self diag./self id.

Wiring check, self-check and the type of clamp is automatically detected and the results displayed.

If NG is displayed, the detail can be confirmed by pressing the “ENTER” key.

Recording setting

Set the recording interval time and the recording time or period.

Power supply from measuring line

Power (under 240 VAC) can be supplied by using the power supply adapter (sold separately).

Note: This is not available for EV region.

Leakage current measuring

The external magnetic field effect is 0.002 A or less, at 400 A/.

Yokogawa’s proprietary technology has achieved a magnetic field impact amount of 30 ppm even in adjacent power lines (at 100 A).

Below is an example of how to measure a neutral line of 3 phase 4 line.

Multiple line measuring

4 system load measuring

Maximum of 4 systems is capable for 1 phase 2 line Maximum of 2 systems is capable for 1 phase 3 line or 3 phase 3 line.

-Software for Analysis and Setting (Free) CW500Viewer

Data analysis, data reporting, making a setting file and doing a real time measurement can be easily done with the CW500Viewer.

The data can be transferred by SD memory card, USB communication or Bluetooth communication (for USA, Canada, Japan only).

The graph and lists are created by a click on the data file.

- The graph and lists of the recorded data file are created by clicking on the desired data file. They can be displayed and copied on a clipboard so it can be used on other software such as Word or Excel.

- The time axis and measure axis can be zoomed in or out easily. With this capability, micro and macro changes can be displayed.

- Waveforms of power quality events (Voltage swell, voltage dips, voltage interrupt, voltage transient, (over and inrush current) which are recorded by 200 ms period can be displayed and printed.

- The integrated data can be added on one graph, enabling the whole energy integration data to be displayed.

- Integrated energy data can be scaled into CO2 or the crude oil value.

Settings management

- Setting data can be read out from and to the main unit via SD memory card, USB communication cable or Bluetooth communication (*1).

- Setting data can be easily edited, saved and managed.

Real time measurement

- Real time measurement can be performed on up to 2 units simultaneously via USB communication or Bluetooth communication (*1)

System Requirements

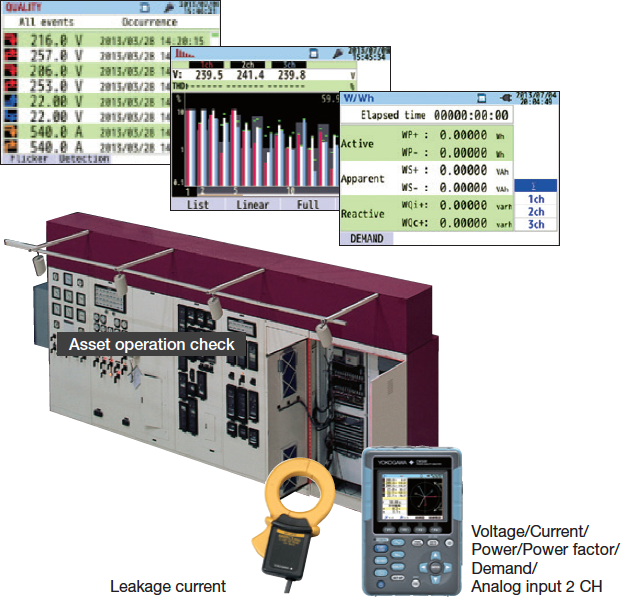

Power Measuring + Power Quality Examination

Examination of main power line quality for factory system control and assets

- Confirm the quality of power lines for factory system control and assets.

- Simultaneously measure the consumption of energy trend and consider solutions for energy saving.

The CW500 not only continuously measures harmonics but it also captures malfunctions of the power line and records the occurrence time with waveforms. Simultaneously, it can measure the power and leakage current of a neutral phase. Additionally, users can confirm the condition of assets when signals are connected to the DCV input channels.

Power Line Measuring Examination

Checking Energy Efficiency of LED lighting

Verify the energy saving effects of LED lighting compared to standard incandescent lighting by performing before and after measurements.

Checking power consumption of driving pumps of a manufacturing line

Inverters were installed on many driving pumps in liquid manufacturing lines, and power consumption measurements are needed to check the before and after effects.

Multiple parameters can be set and measured by the PC software. Additionally, the power line quality can also be tested to assure the new inverters can be operated safely.

Improving power line quality of a printing factory by measuring harmonics (Printing factory)

Purpose: Investigation of the cause of constant malfunctions for printing machines.

Harmonics distortion on line could be the reason?

Measuring: CW500 key features

- Compact and easy to carry.

- Measures harmonics up to 50.

- Long term recording

Result: Confirming high level harmonic contents on 5th and 7th.

Many damaging harmonics are discovered in the 5th and 7th harmonics. 5th harmonic content can damage the calculation of capacitance for improving power factor.

Improving the power factor for power efficiency

The CW500 can calculate the appropriate capacitance value by setting the aimed power factor value.

By setting the proper capacitance calculation and improving the power factor, users will benefit from power savings with less load current and improve the capacity of the whole power system.

-

96065 Clamp-on probe

- 96065 Current clamp-on probe

- max. approx. 110 mm

- AC 1000 A flexible type load current measurement

96066 Clamp-on probe

- 96066 Clamp-on probe

- max. approx. 150 mm

- AC 3000 A, 3 CH Load current measurement

US 15948

US 15948  GB 11574

GB 11574  CA 9842

CA 9842  AU 6663

AU 6663  IE 2241

IE 2241  BR 1590

BR 1590  NZ 1190

NZ 1190  SG 770

SG 770