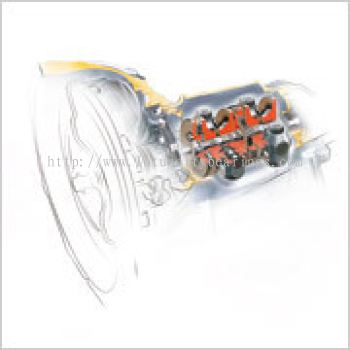

The Half Toroidal CVT is an innovative transmission that executes smooth, continuous gear ratio changes by changing the angle of the power rollers between the input disk and output disk. Toroidal CVT development began in 1877. One hundred years later, NSK undertook its development in 1978, spending as much as 21 years to develop a practical application. Featuring smooth, silent, and continuous gear ratio changes, as well contributing to conserving energy and further reduction of CO2 emissions, the highly efficient Half Toroidal CVT POWERTOROS Unit is the desired transmission that is a result of NSK's advanced technology in tribology.

Features

Tribology in Half Toroidal CVT

Power can be transmitted much more smoothly if the gear teeth that transmit power are made as small as possible. Although a Half Toroidal CVT has no real gear teeth, power is transmitted by a mechanism called traction drive. In the Half Toroidal CVT, which achieves a quiet and smooth transmission of great power, is a layer of oil that is pressurized under an extreme load to approximately 1/1000 mm thick at the point of contact between the disk and power roller. This special oil has a characteristic of forming into a glass-like substance under high pressure. Power is transmitted from the disk to the oil, and then to the power roller. In other words, since it is in rolling contact under high surface pressure, the durability of the contact surface becomes an issue. In order to solve this issue, NSK gathered all of its tribology technology to develop CVT steel, which is highly purified steel for CVT where non-metal inclusions have been removed to the most possible extent. This material achieves constant rigidity by increasing the amount of austenite composition in the steel, which helps make foreign substances entering the gear virtually harmless.

We succeeded in developing a material that is highly reliable with long life while operating under the most severe conditions of massive loads, high temperatures, and high speeds.

Power Split System

The next generation of the Half Toroidal CVT is even more efficient thanks to NSK's power-split system. This system utilizes planetary gears combined with the Half Toroidal CVT and a planetary gear device. This power circulatory speed-changing mechanism had been conceived in theory before, but had not actually been developed since the best non-level speed changer had not yet been developed. By changing two modes, a wide range of speeds and a very highly efficient form of power conveyance was achieved in our power-split system, which is the truly ideal speed changer.

(Incorporating a planetary gear allows most of the engine power to be transmitted directly to the wheel, bypassing the harf-toroidal CVT.)

US 17942

US 17942  GB 13178

GB 13178  CA 10916

CA 10916  AU 7608

AU 7608  IE 3407

IE 3407  BR 2291

BR 2291  NZ 1624

NZ 1624  SG 766

SG 766