Features

RONDCOM NEX

Roundness & Cylindrical Profile Measuring Instruments

A 3-in-1 Machine Satisfying Various Measurement Needs with Functions to Measure Roundness, Diameter, and Roughness, as well as Selectable Specifications

In addition to roundness measurement, RONDCOM NEX offers high-precision diameter measurement with functions common to the series. The NEX Rs/Rs α models are also capable of measuring roughness. Users can choose from various specifications to suit their needs, such as a higher maximum loading mass (30/60 kg), greater column size (300/500/900 mm), and either manual or automatic alignment and detector orientation adjustment.

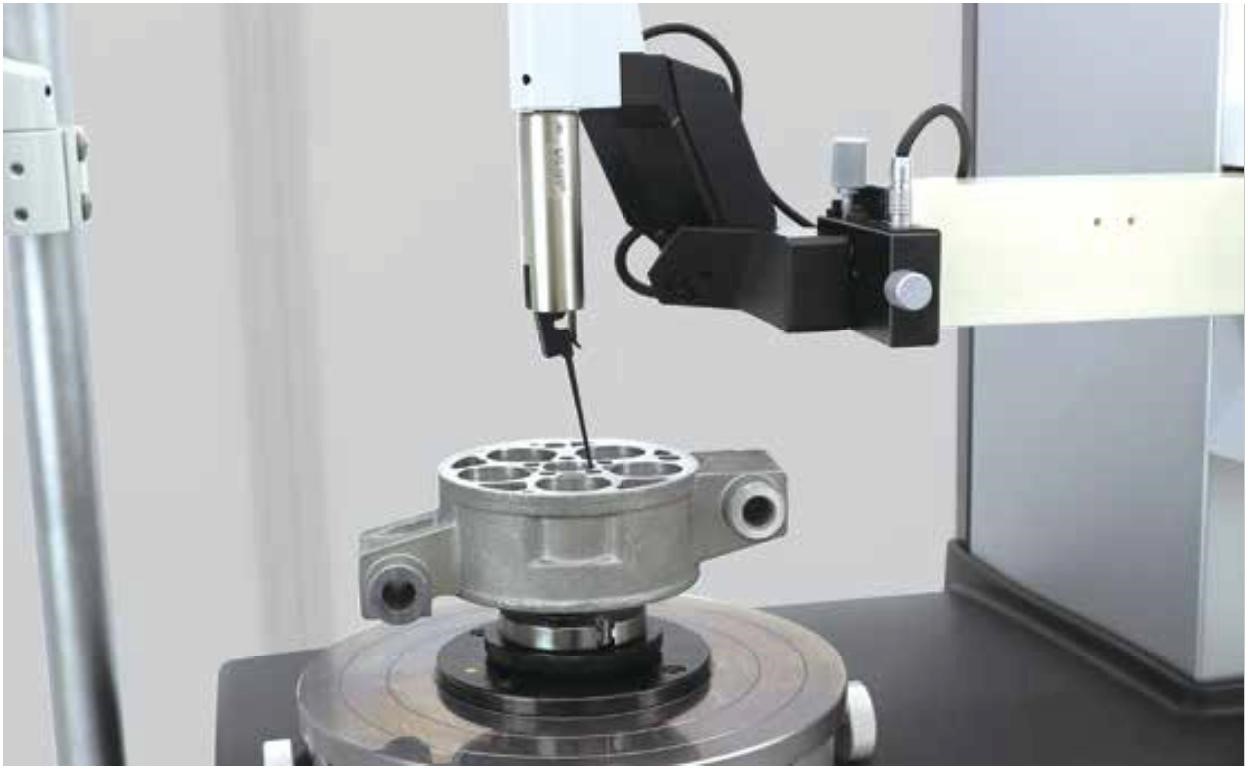

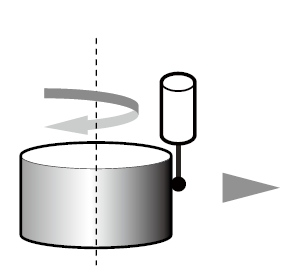

Labor-saving option: AFD(Automatic Force adjustment Detector)

The AFD (Automatic Force adjustment Detector) allows automatic adjustment of measurement direction and force in the software. As such, it is possible to automatically measure the outer and inner diameters of a workpiece. When measuring notched workpieces, the front travel can be automatically adjusted to prevent the stylus from dropping.

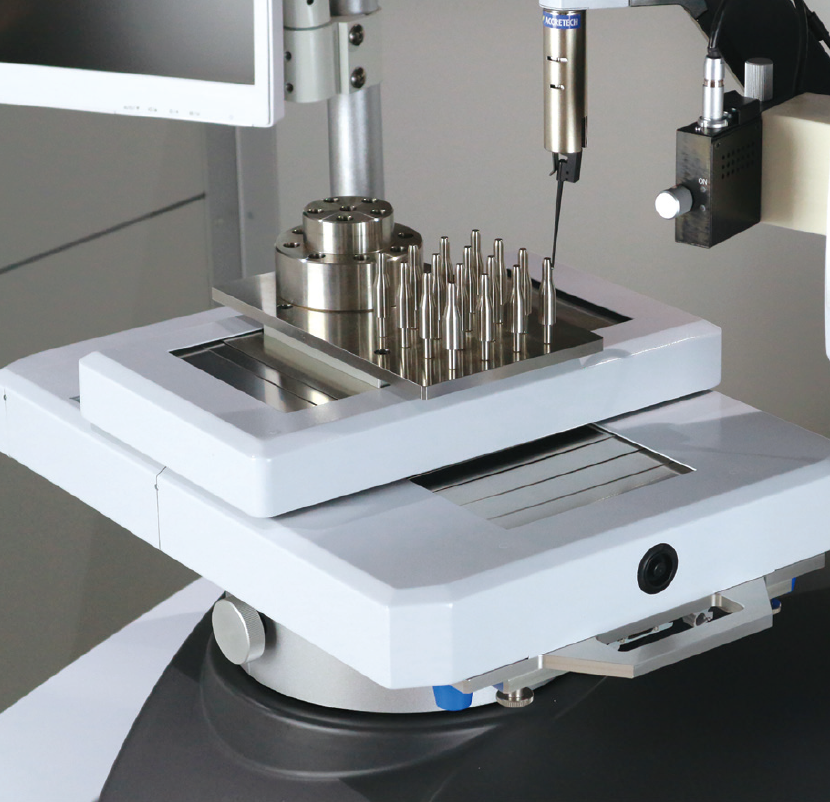

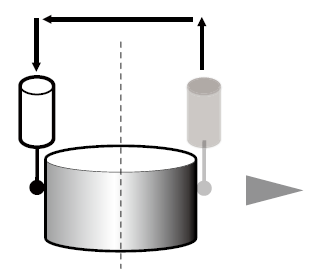

Dramatically Improving Efficiency of Measurement of multiple workpieces and multiple locations Labor-saving option: XY-Axis Automatic Stage

When measuring a large number of workpieces, a typical table rotation roundness and cylindrical profile measuring instrument requires the workpiece to be replaced multiple times between individual measurements. However, the RONDCOM NEX series features a common optional XY-Axis Automatic Stage, allowing many workpieces on the stage to be measured at once without requiring any special setup. This is a labor-saving option that minimizes operator effort and reduces measurement take time.

Versatility

Meeting Diverse needs with Wide-ranging Line-up to Choose from

RONDCOM NEX

- Max. loading weight: 30kg

- Max. measuring height: 300/500 mm

- Alignment: Manual/CNC

- Changing the posture of the detector: Manual/CNC

- Types: Measuring unit and data processor integrated(DX2) /Measuring unit and data processor separated(SD2)

- Alignment can be upgraded from manual to CNC later

RONDCOM NEX Rs

- Max. loading weight: 30kg

- Max. measuring height: 300/500 mm

- Alignment: CNC

- Changing the posture of the detector: Manual/CNC

- Types: Measuring unit and data processor integrated(DX2) / Measuring unit and data processor separated(SD2)

- Roughness measurement is possible

RONDCOM NEX α

- Max. loading weight: 60kg

- Max. measuring height: 300/500/900* mm *Only SD2 type

- Alignment: Manual/CNC

- Changing the posture of the detector: Manual/CNC

- Types: Measuring unit and data processor integrated(DX2) / Measuring unit and data processor separated(SD2)

RONDCOM NEX Rs α

- Max. loading weight: 60kg

- Max. measuring height: 300/500/900* mm *Only SD2 type

- Alignment: CNC

- Changing the posture of the detector: Manual/CNC

- Types: Measuring unit and data processor integrated(DX2) / Measuring unit and data processor separated(SD2)

- Roughness measurement is possible

Versatility

Wide-ranging lineup and accessories enabling measurement of various types of workpieces

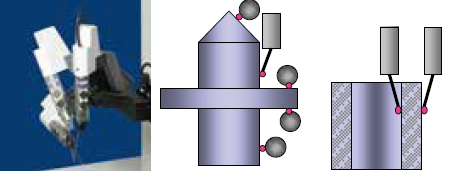

Offset detector holder enabling measurement of thick workpieces with no interference

Standard accessory for RONDCOM NEX 100/200

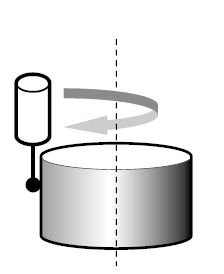

Manual type

Outer (inner) diameter and upper (lower) surface measurement can be switched over simply by bringing down the holder (Patented)

If this offset-type detector holder is brought down, the detector naturally changes its orientation by 90 degrees, thus not requiringmanual rotation of the detector.

Standard accessory for RONDCOM NEX 300

CNC type

Changes detector posture automatically with software or CNC program

Offset-type CNC detector holder has excellent features of the conventional offset-type detector holder and also can automatically change the posture of the detector. It can automatically control the posture of the detector for inner/outer diameter, or upper/lower or tapered surface, significantly increasing measurement efficiency.

Multifunctional

Diverse measurement functions that go beyond the conventional roundness/cylindrical profile measuring instruments

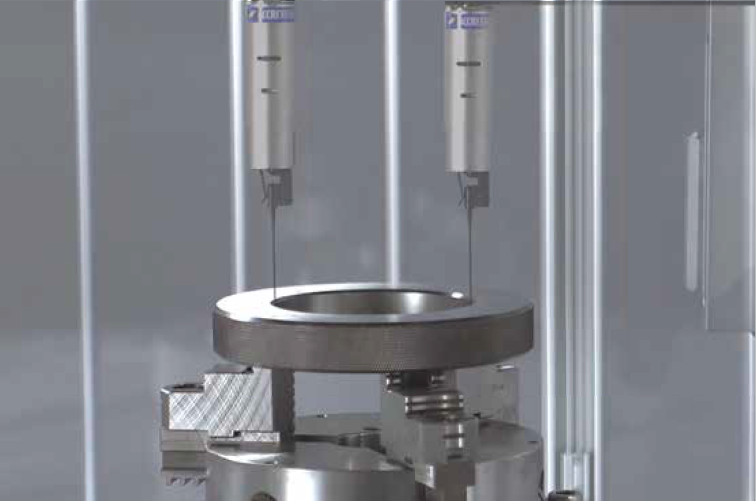

Measurement of inner and outer diameters with high repeatability

Opposed Diameter Measurement Function (Patented)

To measure the diameter of a workpiece with a general roundness/cylindrical prole measuring instrument, measurement is taken by applying the stylus to the workpiece from one side and the radius value thus obtained is doubled to determine the diameter. However, if a deviation occurs in the relative positions of the measuring machine and the workpiece due to temperature changes, the deviation is reected on the diameter value. Accordingly, it is impossible to perform measurement with high repeatability, even if a highly accurate scale is mounted. In opposing diameter measurement funtion, which is a standard feature of RONDCOM NEX series, a workpiece is measured at the 0 degree and opposing 180 degree positions of the table, respectively. The evaluation algorithm implemented as thestandard to correct the errors by temperature change and generatrix line shifting, performs highly-precise diameter measurement.

Measurable diameter

- With standard holder : φ 30 mm or less

- With opposed diameter measuring holder(optional) : φ 100 mm or less

Labor Saving

Excellent labor-saving options reducing operator interventions to achieve higher efficiency in measurement

AFD (Automatic force adjustment detector) enabling automatic switching of roundness and surface texture measurement, and roundness and diameter measurement

The previous detector required manual adjustment of measuring directions, measuring Forces and front/over travel by using front knob, but the AFD enables automatic adjustment of these on the software.

Automatic adjustment of front travel

Capable of measuring multiple locations and workpieces without setup change XY-Axis Automatic Stage (Patented)

Continuous measurement of multiple workpieces / locations with no changeover.

Can be freely attached, removed, and capable of being retrofitted

Since it can be attached and removed by customer, customer can choose between the standard table and the XY-axis automatic stage depending on the workpiece.As this option is available for retrofitting, it can be attached to an existing machine.

Usability

User-friendly design common to the series, minimizing the operator’s workload to achieve stress-free operation

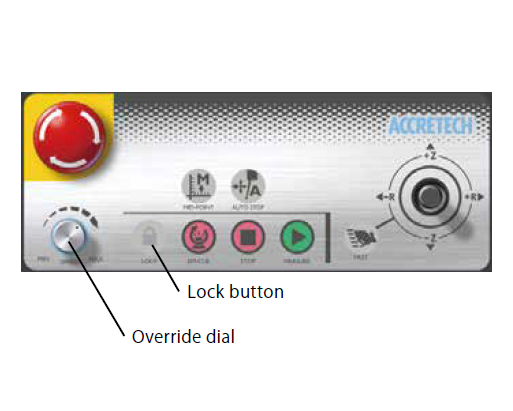

New operation panel with clear and intuitive icons and safety feature

Excellent operability is achieved by icons clearly indicating the operations to execute. In addition, “override dial” controlling the driving speed of R-axis and Z-axis in real- time and “lock button” invalidating panel operations other than measurement stop, emergency stop and release of emergency stop enhance safety in measurement.

Override Dial: Turning the override dial in the initial execution of the CNC program or measurement of narrow spaces temporarily reduces the speed so that measurement can be performed safely while the operator is checking the operation.

Lock Button: Pressing the lock button prevents accidents caused by accidental misoperation such as unintended operation of the machine resulting from the body or the workpiece hitting the joystick in setting.

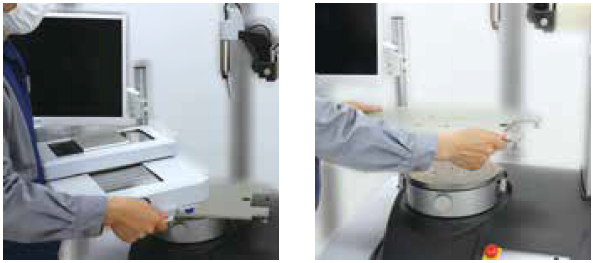

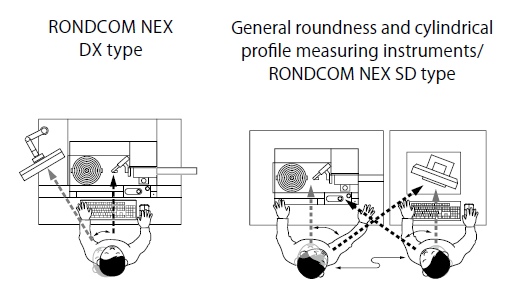

DX type designed for comfortable operation and small footprint

The measurement section of the DX models of RONCOM NEX series is integrated with anti-vibration table and data processing section. This saves the footprint and enables the operator to perform all operations comfortably in front of the measurement section without the need to move between the sections, such as standing in front of the measurement section to adjust the measuring position while looking at the workpiece and in front of the data processing section to operate the software while watching the screen.

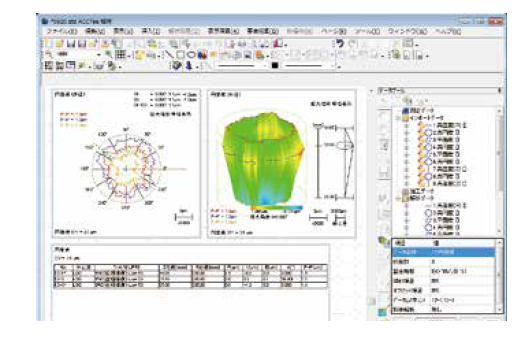

Integrated measurement analysis software ACCTee enabling all operations to be performed intuitively

ACCTee is a software that makes it possible to perform the whole inspection process consisting of preparations, such as calibration and alignment, measurement, analysis and printing of result in an extremely intuitive manner. With this software, a CNC program for automatic execution of alignment, measurement and output of result can be created easily. Measurement values and 3D color maps can be freely arranged on the measurement result sheet, which can be printed or converted to a PDF file and used as an inspection report.

Automatic oiling mechanism making it sufficient to supply oil to the column once a year.

An oil tank and an automatic oiling mechanism are built into the Z-axis column. While a general roundness cylindrical profile measuring machine requires periodic oiling of the column, no manual oiling is necessary for RONDCOM NEX as the internal mechanism of the column is automatically oiled. All the operator needs to do is to fill the built-in oil tank once a year.

Stainless steel rotary table that makes oiling and use of anti-corrosion paper unnecessary

The rotary table of RONDCOM NEX is made of stainless steel. It can be used effortlessly with no daily maintenance such as oiling and covering with anti-corrosion paper after use.

Ceramic R-axis arm requiring no daily oiling and hardly affected by temperature changes

The R-axis arm, which is made of ceramic, is low-maintenance as it does not require daily oiling to prevent corrosion. Also, because of its low thermal expansion coefficient, the impact of room temperature changes on the accuracy can be minimized.

Specifications

Hardware

| Model / Item |

RONDCOM NEX (-11, -12) RONDCOM NEX α (-21,-22, -23) |

|||||||||||||||||

| – |

RONDCOM NEX Rs (-11, -12) RONDCOM NEX Rs α (-21,-22, -23) |

|||||||||||||||||

| 100 | 200 | 300 | ||||||||||||||||

| SD2 | DX2 | SD2 | DX2 | SD2 | DX2 | |||||||||||||

| Model*¹ | 11 | 12 | – | 11 | 12 | 11 | 12 | – | 11 | 12 | 11 | 12 | – | 11 | 12 | |||

| 21 | 22 | 23 | 21 | 22 | 21 | 22 | 23 | 21 | 22 | 21 | 22 | 23 | 21 | 22 | ||||

| Alignment | Manual | CNC | ||||||||||||||||

| Changing the Posture of Detector | Manual | Manual | CNC | |||||||||||||||

| Measuring Range | Max. Measuring Diameter (mm) |

O.D.��∅ 300 ( ∅ 350)*º I.D.��∅ 360 ( ∅ 410)*º |

O.D.��∅ 300 I.D.��∅ 360 |

|||||||||||||||

| Radial feed range (R-axis) (mm) | 180 | 180 | ||||||||||||||||

| Up/down feed range (Z-axis) (mm) | 300 | 500 | 900 | 300 | 500 | 300 | 500 | 900 | 300 | 500 | 300 | 500 | 900 | 300 | 500 | |||

| Max. loading Diameter (mm) | ∅ 580 | ∅ 580 | ||||||||||||||||

| Max. Measuring Height (mm) | 300 | 500 | 900 | 300 | 500 | 300 | 500 | 900 | 300 | 500 | 300 | 500 | 900 | 300 | 500 | |||

| Depth of Measurement (mm) | 150*² | |||||||||||||||||

|

Accuracy

|

Rotation Accuracy*³ | Radial Direction (µm) | (0.02 + 3.2H/10000) | |||||||||||||||

| Axis Direction (µm) | (0.02 + 3.2R/10000) | |||||||||||||||||

| Straightness Accuracy | Up/Down Direction (Z-axis) (µm/mm) | 0.10/100 | 0.20/100 | 0.10/100 | 0.10/100 | 0.20/100 | 0.10/100 | 0.10/100 | 0.20/100 | 0.10/100 | ||||||||

|

0.15/ 300 |

0.23/ 500 |

0.90/ 900 |

0.15/ 300 |

0.23/ 500 |

0.15/ 300 |

0.23/ 500 |

0.90/ 900 |

0.15/ 300 |

0.23 /500 |

0.15/ 300 |

0.23/ 500 |

0.90/ 900 |

0.15/ 300 |

0.23/ 500 |

||||

| Radial Direction (R-axis) (µm/mm) | 0.7/180 | |||||||||||||||||

| Parallelism Accuracy | Z-axis/T-axis (µm/mm) |

0.7/ 300 |

1.0/ 500 |

2.0/ 900 |

0.7/ 300 |

1.0/ 500 |

0.7/ 300 |

1.0/ 500 |

2.0/ 900 |

0.7/ 300 |

1.0/ 500 |

0.7/ 300 |

1.0/ 500 |

2.0/ 900 |

0.7/ 300 |

1.0/ 500 |

||

| Squareness Accuracy | R-axis/T-axis (µm/mm) | 1.0/150 | ||||||||||||||||

| Scale Indication Accuracy | R-axis (µm) | 0.5+L/180+2L T/100) L: Moving length��mm�� T: The difference in temperature between 20�� and the current temperature (ºC) |

||||||||||||||||

| Speed | Measurement Speed | Rotation speed (θ-axis) (/min) | 1 ~ 10 |

1 to 10 0.01 to 1 (at roughness measurement: only with NEX Rs/NEX Rs α) |

||||||||||||||

| Up/down speed (Z-axi) (mm/s) | 0.5 ~ 10 |

0.5 to 10 0.1 to 1.5 (at roughness measurement: only with NEX Rs/NEX Rs α) |

||||||||||||||||

| Radial direction speed (R-axis) (mm/s) | 0.5 ~ 10 |

0.5 to 10 0.1 to 1.5 (at roughness measurement: only with NEX Rs/NEX Rs α) |

||||||||||||||||

| Drive Speed | Rotation speed (θ-axis) (/min) | Max. 20 | ||||||||||||||||

| Up/down speed (Z-axis)(mm/s) | 5 to 60 | |||||||||||||||||

| Radial direction speed (R-axis) (mm/s) | 5 to 30 | |||||||||||||||||

| Table | Table Diameter (mm) | ∅ 235 | ||||||||||||||||

| Centering Range (mm) | ± 5 | |||||||||||||||||

| Tilting Range (º) | ± 1 | |||||||||||||||||

| Table | Max. Loading Weight | NEX/NEX Rs (kg) | 30 | |||||||||||||||

| NEX α/NEX Rs α (kg) | 60 | |||||||||||||||||

|

Detector/ Stylus |

For Roundness Measurement (Standard Accessory) |

Detector E-DT-R120B |

Measurement force (mN) |

30 to 100 | ||||||||||||||

|

Linear Range (µm) |

± 1000 | |||||||||||||||||

| Function | TO.D./I.D. switching function, front/overtravel adjustment function, emergency stop function | |||||||||||||||||

|

Stylus EM46000-S302 |

Tip Shape (mm) | ∅ 1.6 | ||||||||||||||||

| Length (mm) | 53 | |||||||||||||||||

| Tip Material | Cemented Carbide | |||||||||||||||||

|

For both Roundness & Roughness Measurement (Standard accessory for NEX Rs & NEX Rs α)

|

Low measuring force detector E-DT-R168D |

Measurement force (mN) |

4 | |||||||||||||||

| Linear Range (µm) | ± 400 | |||||||||||||||||

| Stylus (for 010 2505 | Tip Shape (mm) | ∅ 1.6 | ||||||||||||||||

| Length (mm) | 26.5 | |||||||||||||||||

| Tip Material | Ruby | |||||||||||||||||

| Stylus (for 010 2501 | Tip Shape (mm) | Rtip 5µm (90º cone) | ||||||||||||||||

| Length (mm) | 26.5 | |||||||||||||||||

| Tip Material | Diamond | |||||||||||||||||

| For high accuracy Roughness Measurement (opton for NEX Rs/NEX Rs α) |

Detector E-DT-R290B |

Measurement force (mN) |

0.75 | |||||||||||||||

| Linear Range (µm) | ± 500 | |||||||||||||||||

|

Stylus DM43801 |

Tip Shape (mm) | Rtip 2µm (60º cone) | ||||||||||||||||

| Tip Material | Diamond | |||||||||||||||||

*¹ NEX-11/NEX Rs-11 (Max. loading weight 30 kg, 300 mm column)

NEX-12/NEX Rs-12 (Max. loading weight 30 kg, 500 mm column)

NEX α -21/NEX Rs α -21 (Max. loading weight 60 kg, 300 mm column)

NEX α -22/NEX Rs α -22 (Max. loading weight 60 kg, 500 mm column)

NEX α -23/NEX Rs α -23 (Max. loading weight 60 kg, 900 mm column

*² Please contact our sale personnel as there may be limitations due to the measurement diameter, and the combination of detector and stylus.

*³ JIS B 7451-1997 compliant. H is the height of the measurement point from the upper surface of the table in mm, and R is the distance from the rotational center of the table in mm.

*º When using measurement diameter extension offset-type detector holder E-DH-RB86A (optional)

Software

| Model / Item |

RONDCOM NEX (-11, -12) RONDCOM NEX α (-21,-22, -23) |

|||||||||||||||||

| – |

RONDCOM NEX Rs (-11, -12) RONDCOM NEX Rs α (-21,-22, -23) |

|||||||||||||||||

| 100 | 200 | 300 | ||||||||||||||||

| SD2 | DX2 | SD2 | DX2 | SD2 | DX2 | |||||||||||||

| Model*¹ | 11 | 12 | – | 11 | 12 | 11 | 12 | – | 11 | 12 | 11 | 12 | – | 11 | 12 | |||

| 21 | 22 | 23 | 21 | 22 | 21 | 22 | 23 | 21 | 22 | 21 | 22 | 23 | 21 | 22 | ||||

| Number of Sampling (Point) | 14400 | |||||||||||||||||

| Type of Filter | Digital Filter | Gaussian/2RC/spline/robust (spline) | ||||||||||||||||

| Cut-off Value | Rotational Direction (θ-axis) | Low Pass | Selectable any value in 15, 50, 150, 500, 1500 UPR, 15 to 1500 UPR | |||||||||||||||

| Band Pass | 1 to 1500 UPR | |||||||||||||||||

| Rectlinear Direction (Z-axis) | Low Pass | 0.025, 0.08, 0.25, 0.8, 2.5, 8 mm (any value in 0.0001 mm) | ||||||||||||||||

| Roundness Evaluation of Form Error | MZC (min. zone circle method), LSC (least square circle method), MIC (max. inscribed circle method), MCC (min. circumscribed circle method), N.C. (no compensation) | |||||||||||||||||

| Measuring Item | Rotation Direction | Roundness, atness, atness (compound), parallelism, concentricity, coaxiality, cylindricity, diameter deviation, squareness, thickness variation, partial circle | ||||||||||||||||

| Rectlinear Direction | Straightness (Z), straightness (R), cylindricity, squareness, parallelism, diameter deviation, axis straightness | |||||||||||||||||

| Roughness Analysis Item | Standard | – | JIS-2013, JIS-2001, JIS-1994, JIS-1982, ISO-2009, ISO-1997, ISO-1984, DIN-1990, ASME-2002, ASME-1995 | |||||||||||||||

| Parameter | Ra, Rq, Ry, Rp, Rv, Rc, Rz, Rmax, Rt, Rz.J, R3z, Sm, S, RΔ a, R Δ q, R λ a, R λ q, TILT A, Ir, Pt, Pc, Rsk, Rku, Rk, Rpk, Rvk, Mr1, Mr2, VO, K, tp, Rmr, tp2, Rmr2, R δ c, AVH, Hmax, Hmin, AREA, NCRX, R, Rx, AR, NR, CPM, SR, SAR | |||||||||||||||||

| Evaluation Curve | Prole curve, roughness curve, ltered waiveness curve, rolling circle waiveness curve, rolling circle center line waiveness curve, ISO13565-1 prole curve, ISO13565-1 roughness curve, roughness motif curve, waiveness motif curve, envelope waviness curve | |||||||||||||||||

| Characteristic Graph | Bearing area curve, amplitude distribution graph, power spectrum curve | |||||||||||||||||

| Tilting Adjustment Method | Least square straight line correction, n-dimension polynomial correction, both ends correction, least square circle correction, least square oval correction, spline correction, robust (spline) correction, spline curve correction | |||||||||||||||||

| Analysis processing functions | Notch function (level, angle, cursor), combination of roundness evaluation methods, nominal value collation, cylinder 3D prole display (line drawing, shading, contour line), real-time display, prole characteristic graph display (bearing area curve, amplitude distribution function, power spectrum), CNC automatic measuring function | Notch function (level, angle, cursor), combination of roundness evaluation methods, nominal value collation, cylinder 3D prole display (line drawing, shading, contour line), real-time display prole characteristic graph display (bearing area curve, amplitude distribution function, power spectrum), CNC automatic measuring function, automatic centering/tilting adjustment function | ||||||||||||||||

| Display Items | Measuring conditions, measuring parameters, comments, printer output conditions, prole graphics (expansion plan, 3D plan), error messages, etc | |||||||||||||||||

Dimensions & Other Items

US 14902

US 14902  GB 11923

GB 11923  CA 9868

CA 9868  AU 9019

AU 9019  IE 5429

IE 5429  BR 4485

BR 4485  NZ 1498

NZ 1498  SG 1231

SG 1231