It’s mainly composed of: Grinding part ( 3 rollers ) + Driving system (motors + gears + belt ) + Frame part

|

Model Parameter |

S65 | S150 | S200 | S260 | |

| 220V 50Hz | 380V / 415V 50Hz | 380V / 415V 50Hz | 380V / 415V 50Hz | ||

| Roller Diameter mm | Ø65 | Ø150 | Ø200 | Ø260 | |

| Roller Working Length mm | 125 | 300 | 500 | 695 | |

| Roller Turning Speed r.p.m | slow roller | 32 | 25.3 | 22 | 19.1 |

| middle roller | 89 | 63.25 | 63 | 54.5 | |

| fast roller | 250 | 152 | 155 | 155.3 | |

|

Motor Power |

model | SL50-2 | SL100-4 | SL200-6 | SL160L-6 |

| power KW | 0.75 | 2.2 | 4 | 7.5 | |

| r.p.m | 1400 | 1420 | 970 | 970 | |

| Dimension L *W *H | 400*400*420 | 820X800X920 | 1200X1180X1100 | 1645X1350X1100 | |

| Net weight (Kg) | 40 | 600 | 800 | 2300 | |

Brief introduction:

It’s mainly composed of: Grinding part ( 3 rollers ) + Driving system (motors + gears + belt ) + Frame part

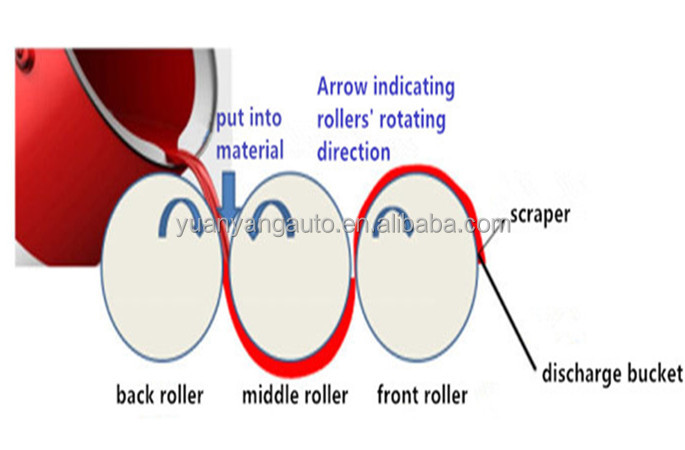

Grinding effect is achieved by pressing the surface of three horizontal rollers against each other and friction at different

speeds .

Material was added between the middle and rear rollers, and discharged by scraper from the front roller.

US 15597

US 15597  GB 12164

GB 12164  CA 10612

CA 10612  AU 9610

AU 9610  IE 4554

IE 4554  BR 2651

BR 2651  NZ 2227

NZ 2227  MY 970

MY 970