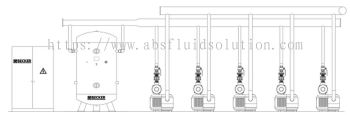

PumpstandThe vacuum pumps to be used can be oil-free (VT 4.16 – VTLF 2.250) s well as oil-lubricated (U 4.20 – U 4.400) units. This makes it possible to achieve a vacuum of 90 % or otherwise 99.5 %. Side-channel vacuum pumps can also be employed for a lesser vacuum. Vessels are available in the sizes 90, 250, 500, 1000 and 1500 litre in horizontal versions. Upon request, they can be hot-dip galvanised inside and out.

- ABS Engineering & Trading Sdn Bhd

- Home

- Products (706)

- News

- Map

- Download

- Contact

- Web Statistic

- VISITORS:

Congratulations!

You��ve earned your daily login reward for today!

5 NP PointHere are the reward you��ve earned!

Check your Daily Login Rewards

Be sure to come back everyday for more rewards!

Thanks!

16-Nov-2014

PumpstandThe vacuum pumps to be used can be oil-free (VT 4.16 – VTLF 2.250) s well as oil-lubricated (U 4.20 – U 4.400) units. This makes it possible to achieve a vacuum of 90 % or otherwise 99.5 %. Side-channel vacuum pumps can also be employed for a lesser vacuum. Vessels are available in the sizes 90, 250, 500, 1000 and 1500 litre in horizontal versions. Upon request, they can be hot-dip galvanised inside and out.

ABS Engineering & Trading Sdn Bhd 296504-V

1, Jalan Serendah 26/41, Hicom Industrial Estate, 40400 Shah Alam, Selangor, Malaysia.

Tel:

Email:

Website: https://www.absfluidsolution.com

Website: https://absfluidsolution.newpages.com.my/

Website: https://absfluidsolution.onesync.my/

Northern Office

17, Lorong Perda Utama 7, Bandar Perda, 14000 Bukit Mertajam, Penang, Malaysia

Tel:

Fax:

Email:

Southern Office

12, Jalan Bentara 1, Taman Iskandar, 80050 Johor Bahru, Johor, Malaysia.

Tel:

Fax:

Email:

ABS Engineering Vietnam Limited (ABS VN) - HCMC Office

168E, D2 Street, Ward 25, Binh Thanh District, HCMC, Vietnam.

Tel:

Fax:

Email:

ABS Engineering Vietnam Limited (ABS VN) - Ha Noi Office

E16, 4th Flr, Sun Anrora Building No 3, Luong Yen Street, Bach Dang Ward, Hai Ba Trung Dictrict, Ha Noi, Vietnam.

Tel:

PT Kampak Peralatan Aliran

JL. Raya Perjuangan No.8, Kebun Jeruk Jakarta Barat, Jakarta 11530, Indonesia.

Tel:

Fax:

Browse by : Home - Classifieds - Companies - Location - Tags - Products - News & Promotion - Job Vacancy - Mobile Website - Google - SEO Results

US 15677

US 15677  GB 11978

GB 11978  CA 10103

CA 10103  AU 8821

AU 8821  BR 6226

BR 6226  IE 5177

IE 5177  NZ 1731

NZ 1731  SG 1108

SG 1108