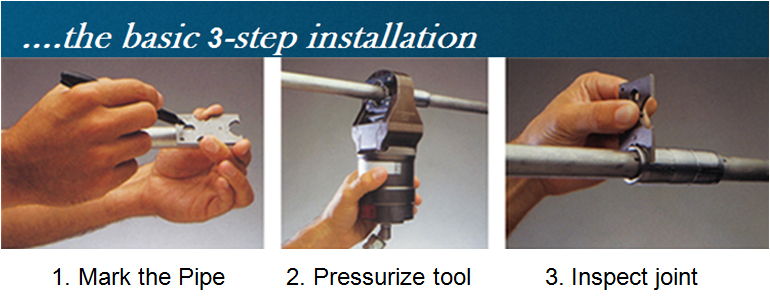

After cutting and preparing the pipe…

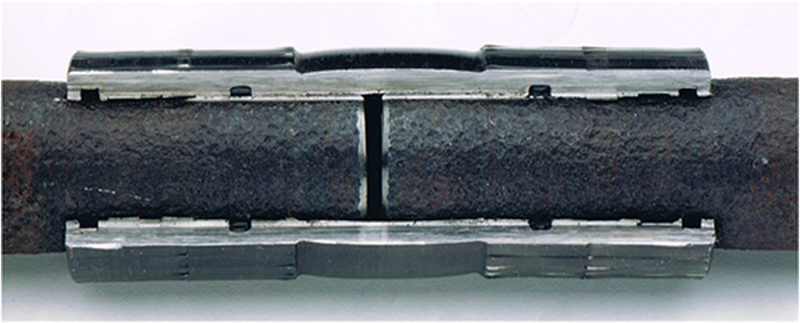

- Sample above : ¾” NPS pipe pitted due to years of exposure

- Performed 6,000 PSI (420 bar) hydrostatic proof test

- 1,000 Psi (70 bar) nitrogen leak test

- Zero leakage detected

| TEST | REQUIREMENTS | RESULTS |

| Gas Leak Test | Gn2 Nitrogen 1,000 PSI for 10 minutes | No leakage |

| Hydrostatic Burst | Based on 4 x Operating Pressure held for 5 minutes | No leakage |

| Hydrostatic Proof | Based on 1.5 x Operating Pressure held for 5 minutes | No leakage |

| Vibration Test | 20,000,000 cycles at displacement @ operating pressure | Passed |

| Impulse Test | 500,000 cycles @ 1.33 x Operating Pressure based on ISO/BS Impulse Cycle | Passed |

| Impulse/Flexure and Fatigue at Low Temperature | Simultaneous impulse and bending stress, 8 times during test of 10,000 cycles each under peak pressure and rated bending each fitting was subjected to -100 deg F for one hour utilizing liquid CO2. | No leakage |

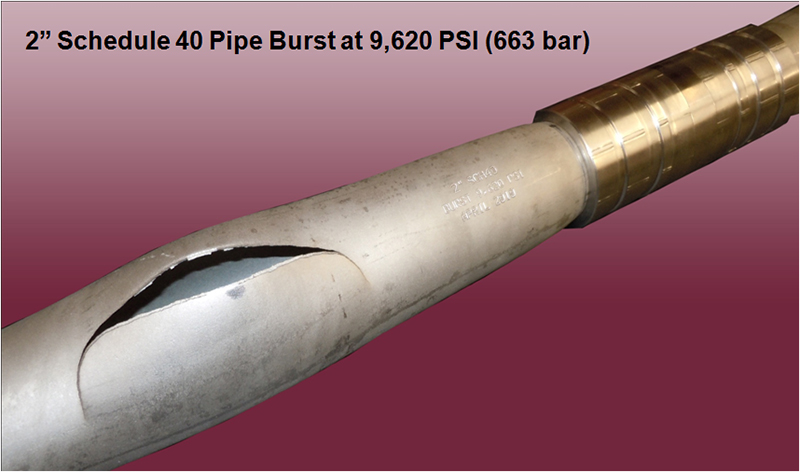

| Tensile Test | Fitting was installed in tensile machine with cross head speed of 0.20 in/min and pulled until one side of pipe dismembered from the fitting/pipe joint | Exceeded Tensile Strength by a factor of 1.33 to 1.63 |

| Torsion Test | At various Torsion Angles and Ft-Lbs of Torque @4500 Psig (Gn2) and 6000 Psig (Hydraulic Fluid) | No Leakage |

| Heat Aging | Maintained at 400 deg F ± 5 deg F for 168 hours, Proof test @ 6000 Psig for 30 minutes | Passed |

PYPLOK Approvals and standards

- ISO 9001:2008 Certified

- ANSI/ASME B31.1 and B31.3

- ANSI/ASME B31.4

- ANSI/ASME B31.8

- CRN - Canadian Registration No. 0A12153.5

- TSSA – Technical Standards and Safety Authority

- ABSA – Alberta Boilers Safety Association

- API 6FB Third Edition Fire Test for end connection fittings

- ISO 19921 Fire Test, Fire Resistance of Metallic Pipe Components with Resilient and Elastomeric Seals

- NAVSEA - United States Naval Sea Systems Command

- US Military Navy Shock Test MIL-S-901D

- ANZAC - Australian, New Zealand Navy

- US Coast Guard

- Canadian Coast Guard

- ABS - American Bureau of Shipping, Certificate 02-HS269945D/2-PDA

- DNV - Det Norske Veritas, Certificate P-13306

Tube-mac successfully achieved type approvals from IACS (International association of classification societies) Members…

- LR – Lloyds Registry

- DNV – Det Norske Veritas

- ABS – American Bureau of Shipping

- CCS – China Classification Socie

- No special skilled labour required vs. qualified welder.

- Actual swaging time is measured in “seconds” vs. “hours” for a welded joint.

- No special hot work permits

- No fire watch personnel required.

- No leaks as a result of stress fatigue cracks as seen in welds.

- No off loading or purging of fluids and gases.

- No cost to x-ray welds.

- No cost to re-work welds.

- No acid flush chemicals and neutralizers required.

- No added cost or environmental issues to dispose of chemical waste.

- SAFE cold work fitting technology.

- SAFE and easy to install in tight confined places.

- SAFE permanent, tamper proof connection.

- One piece fitting versus multi-piece bite-type fitting.

- No threads or nuts that loosen over time.

- No need to rely on the strength of the installer.

- SAFE pre-engineered swage tool assures repeatable, leak-free and reliable connections.

- SAFE for maintenance repairs in hazardous areas.

- Can be installed on a wider range of pipe/tube wall thicknesses.

- SAFE for high pressure applications.

- Easy to install in tight tube runs side-by-side.

- Through bore design allows for zero clearance installation.

- No other sealants or lubricants required.

| CNG – Compressed Natural Gas | Hydraulic Oil |

| Paint and Sealer Lines | Low Temperature Steam |

| Condensate Piping | LPG – Liquefied Petroleum Gas |

| Deluge Systems | Lubrication and Grease |

| Down Well Coiled Tubing | Natural Gas |

| Drains and Plumbing Vents | Waste Water |

| Ethylene Glycol/Water | RAD Waste Systems |

| Fuel Oil and Fuel Gas | Solvents and Water Based Paints |

| Gases – Nitrogen, Air, Helium | Subsea Piping |

| Heating Coil | Steam Tracer Lines |

|

High Pressure Water Mist/Fog – Fire Suppression Systems |

Plant Instrumentation and Utility Air |

Benefits of a TMI non-welded system versus welded system

- No special skilled labour required vs. qualified welder.

- Actual flaring time is measured in “seconds” vs. “hours” for a welded joint.

- No special hot work permits

- No fire watch personnel required.

- No leaks as a result of stress fatigue cracks as seen in welds.

- No cost to x-ray welds.

- No cost to rework welds.

- No acid flush chemicals and neutralizers required.

- No added cost or environmental issues to dispose of chemical wastes.

- SAFE cold work technology.

- Tube-Mac Project Coordinators develop and cost up BOM.

- Field bend and fabrication – reduces engineering design time.

- On-site container – reduces warehouse and inventory costs.

US 14739

US 14739  GB 12665

GB 12665  AU 10241

AU 10241  CA 10169

CA 10169  IE 5748

IE 5748  NZ 2665

NZ 2665  BR 2190

BR 2190  SG 1162

SG 1162