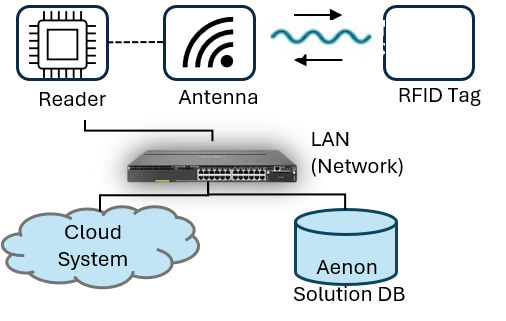

RFID Traceability Solution

- Warehouse Management

- Shop Floor Control

- Asset Tracking

- Employee Tracking

RFID Solutions

- Real time data collection

- Improving visibility

- Location tracking

- Maximizing accuracy

- Process automation

- Report & analysis

Customized RFID Project

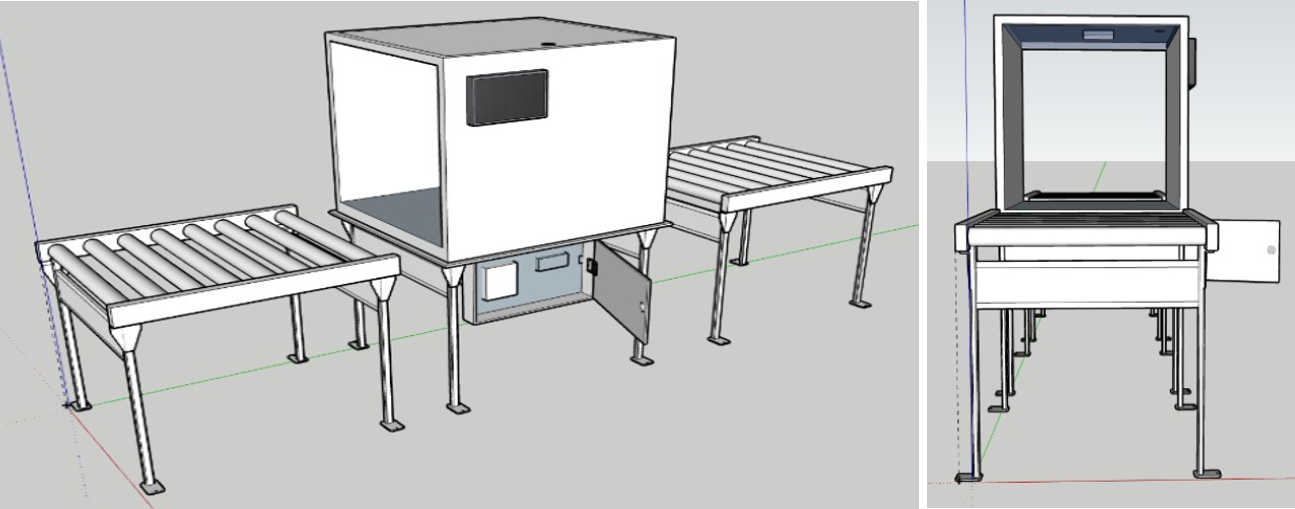

Aenon RFID tunnel

The RFID Tunnel is designed to automate and simplify item tracking — enabling effortless, hands-free scanning of multiple items as they pass through. It ensures fast, accurate data capture without manual intervention, making it ideal for high-volume environments like warehouses, production lines, or distribution centers.

Feature of Aenon RFID tunnel

- Integrated with flexible conveyor system for material and warehouse items tracking

- Rapid RFID tagging and reading

- Modular RFID system

- Hands-Free Operation

- Seamless System Integration

- Industrial-Grade Durability

- Real-Time Data Logging

Aenon RFID Check point

The Aenon RFID Checkpoint ensures real-time tracking of items as they pass through designated zones, providing strict control and accurate records of inventory movement. It automatically logs data, preventing unauthorized asset movements and improving overall warehouse efficiency. Forklifts and other vehicles can pass through seamlessly while maintaining full traceability.

We design and build custom RFID gantries tailored to the client's environment. Our end-to-end solutions include fabricating the RFID structure, cabling, on-site setup, installation, and seamless software integration to ensure smooth and efficient operation.

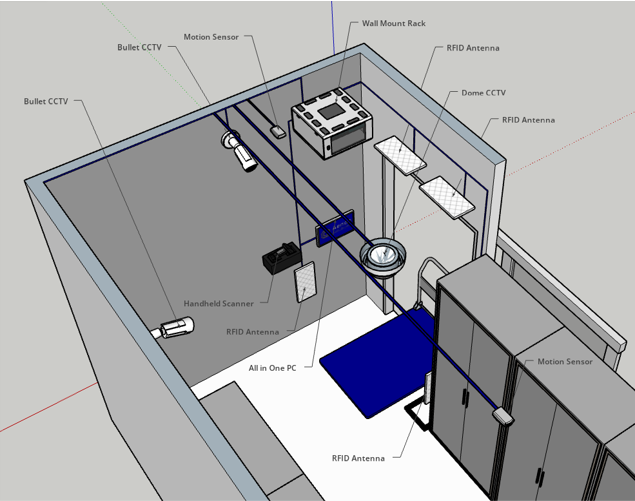

RFID Equipment Room

What is RFID Equipment Room?

While RFID smart cabinets are ideal for many use cases, they can be ineffective for managing bulky or irregularly shaped items.

To address this, we propose an RFID-enabled equipment room that offers:

- A practical solution for items that exceed cabinet capacity.

- Real-time tracking of equipment movement in and out of the room.

- Enhanced accountability, loss prevention, and inventory visibility. This setup complements existing cabinet systems and provides flexibility in asset management across different item types.

Setup of equipment room

RFID Tunnel vs RFID Detection Checkpoint

Why RFID Tunnel / Detection Checkpoint for Attendance?

In large-scale operations, traditional biometric systems often lead to long queues and delays, especially during peak hours when thousands of workers check in at the same time.

To address this bottleneck, we propose an RFID tunnel system designed to:

- Enable fast, contactless, and automated check-in/out processes.

- Reduce congestion and improve flow at entry points.

- Ensure accurate attendance tracking without slowing down worker movement.

This setup helps improve workforce punctuality, operational efficiency, and overall employee experience.

Our automation team built and integrate customize factory requirement with vision, conveyor, sensors, barcode, RFID, collaborative robot and others to help you automate and improve your processes. Our teams are proficience and knowledgeable in products and solutions by Cognex, OMRON, Beckhoff, Intel, Honeywell, Zebra, Kuka robot, Advantech, Atonic etc

Our automation experiences :

- Inline conveyor vision inspection system

- RFID data collection solutions

- Packing and sealing automation project

- Quality inspection and tester machine