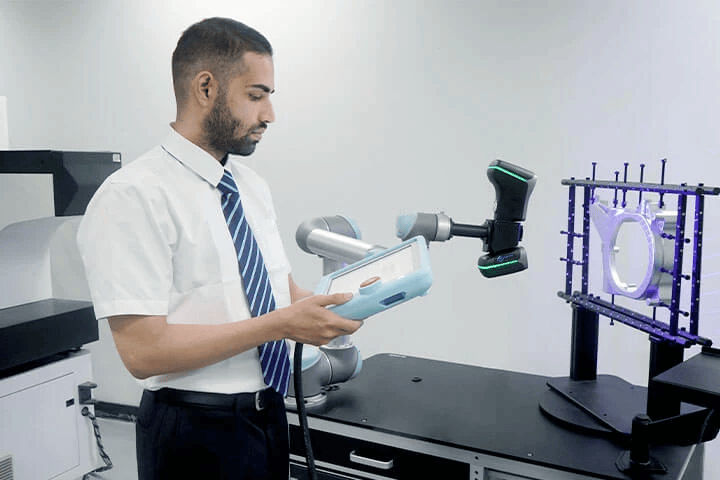

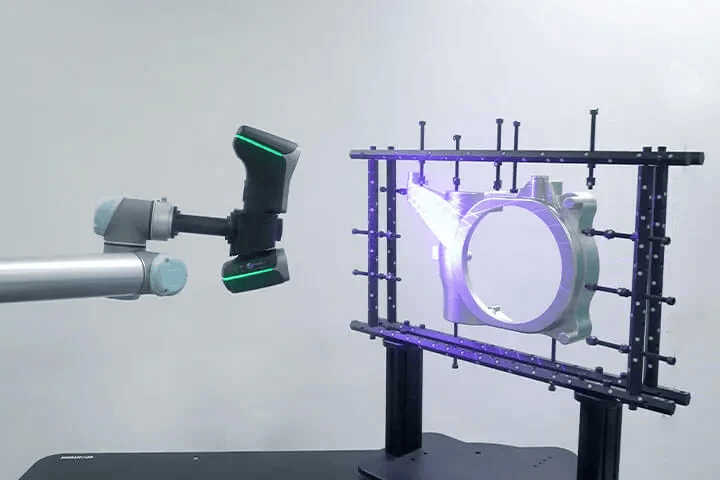

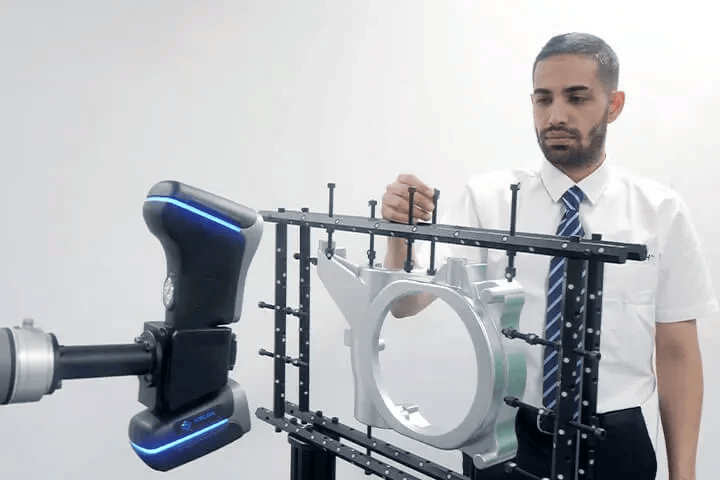

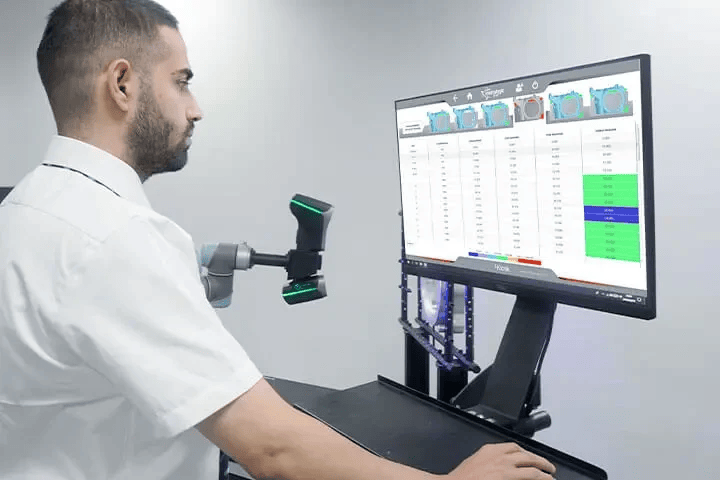

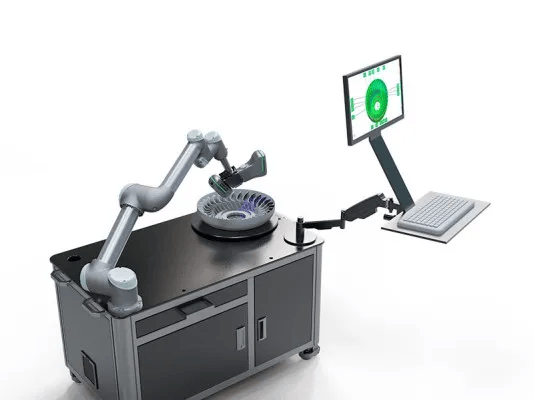

The AutoScan-K 3D System by Scantech is an advanced automated 3D scanning solution designed for high-precision, non-contact, and non-destructive 3D measurement applications. Leveraging cutting-edge machine vision technology, this 3D system ensures exceptional accuracy while facilitating efficient online batch scanning and inspection processes. Operating continuously 24/7, the AutoScan-K 3D system significantly reduces manufacturing costs, accelerates time-to-market, and enhances return on investment for enterprises.

Applications

The AutoScan-K 3D system is ideal for various industries requiring precise 3D measurements, including:

Aerospace: For scanning and inspecting complex aerospace components.

Automotive: Ensuring quality control and precision in automotive parts.

Mold Manufacturing: Verifying mold dimensions and integrity.

Energy & Heavy Industry: Conducting inspections of large and heavy industrial components.

Railway & Shipbuilding: Monitoring structural elements and assemblies.

Features – Scantech AutoScan-K 3D System

1. Fully Automated 3D System

The AutoScan-K 3D system adapts to various workpiece sizes with programmable paths, ideal for dynamic and high-mix production environments using a reliable 3D scanner.

The AutoScan-K 3D system captures up to 4.15 million measurements per second, with accuracy up to 0.020 mm, making it a top-tier industrial 3D scanner for precision applications.

This 3D system supports secondary development and SDK integration, making it highly compatible for industrial automation and smart 3D measurement systems.

Technical Specifications

| Type | AutoScan-KM II | AutoScan-KM | |

| Ultra-fast scanning | 17 blue laser crosses | 11 blue laser crosses | |

| Scan mode | Hyperfine scanning | 7 blue parallel laser lines | |

| Large area scanning | 11 parallel infrared laser lines | ||

| Deep hole scanning | 1 extra blue laser line | ||

| Accuracy(1) | Up to 0.020 mm (0.0008 in) | ||

| Scanning rate up to | 4,150,000 measurements/s | 2,700,000 measurements/s | |

| Scanning area up to | 1440 mm × 860 mm (57.0 in × 33.9 in) |

||

| Laser class | CLASS �� (eye-safe) | ||

| Resolution up to | 0.010 mm (0.0004 in) | ||

Photogrammetry system |

Scanning area | 3760 mm × 3150mm (148.0 in × 124.0 in) |

|

| Depth of field | 2500 mm (98.4 in) | ||

| Work alone | 0.015 mm + 0.030 mm/m (0.0006 in + 0.00036 in/ft) |

||

| Volumetric accuracy(2) | Work with 1 m reference bar | 0.015 mm + 0.020 mm/m (0.0006 in + 0.00024 in/ft) |

|

| Work with MSCAN-L15 | 0.015 mm + 0.012 mm/m (0.0006 in + 0.00014 in/ft) |

||

| Stand-off distance | 300 mm (11.8 in) | ||

| Depth of field | 925 mm (36.4 in) | ||

| Output formats | .stl, .obj, .ply, .asc, .igs, .txt, .mk2, .umk and etc. | ||

| Operating temperature range | -10��-40�� (14! -104! ) | ||

| Interface mode | USB 3.0 | ||

Patents |

CN204329903U, CN104501740B, CN104165600B, CN204988183U, CN204854633U, CN204944431U, CN204902788U, CN105068384B, CN105049664B, CN204902784U, CN204963812U, CN204902785U, CN204902790U, CN106403845B, CN209197685U, CN209263911U, CN106500627B, CN106500628B, CN206132003U, CN206905709U, CN107202554B, CN209310754U, CN209485295U, CN209485271U, CN305446920S, CN209991946U, US10309770B2, KR102096806B1, KR102209255B1, US10914576B2 | ||

Remark :

(1) ISO 17025 accredited: Based on VDI/VDE 2634 Part 3 standard and JJF 1951 specification, probing error (size) (PS) performance is evaluated.

(2) ISO 17025 accredited: Based on VDI/VDE 2634 Part3 standard and JJF 1951 specification, sphere spacing error (SD) performance is evaluated.

US 15036

US 15036  GB 11203

GB 11203  CA 9522

CA 9522  AU 8923

AU 8923  BR 7274

BR 7274  IE 4617

IE 4617  NZ 3692

NZ 3692  SG 1337

SG 1337