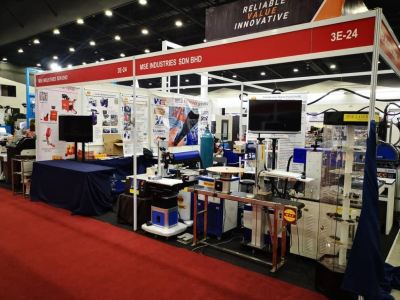

Offering superior laser welding, thermal spray products and services across industries and country wide, MSE is becoming synonymous with laser welding applications, thermal spray engineering to other prominent players in Malaysia.

COMPANY BACKGROUND

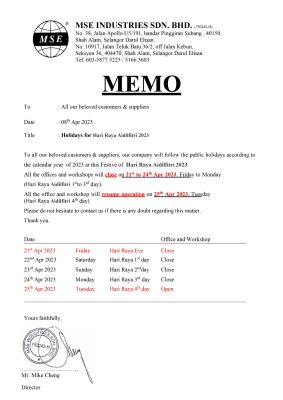

Incorporated in 2002, MSE Industries Sdn Bhd (frequently shortened as MSE) is an emerging and dynamic company operating its business extensively throughout the country, offering reliable and sustainable laser welding, thermal spray products and solutions for critical welding maintenance and integration application. Headquartered in Bandar Pinggiran Subang, Known familiar as Subang 2 in Selangor Darul Ehsan, MSE identifies and satisfies customers’ ever-changing needs in laser welding and thermal spray applications through its extensive workshop facilities nationwide include the mechanical repair, maintenance, design, fabrication as well as modification of engineering works.

From a humble beginning, MSE has expanded its local and overseas footprint gradually through its robust subsidiary companies. At MSE, we pride ourselves on being a dynamic group of companies with other subsidiaries namely MSE Lasertech (M) Sdn Bhd, overseeing business, workshop operations and overseas partnership business in Indonesia and India correspondingly.

ADDING VALUES THROUGH INNOVATIVE

LASER WELDING & METAL SPRAY COATING SOLUTIONS

With a decade-long hands-on experience in all aspects of the laser welding and thermal spray coatings industry, MSE has been greatly committed in providing its comprehensive consultancy and supply service to a diverse industry sectors include the engineering, plastic injection moulding, aluminium die casting, Oil & Gas, petrochemical, power generation aviation and many more. Working closely with some reputable organizations and partners in Malaysia, MSE is capable to provide a comprehensive range of laser welding and thermal spray systems and services including HVOF spray, PLASMA spray, ARC spray and equipment, LASER and TIG consumables, fuse, powder, laser components and spare parts etc. to the Malaysia’s thermal spray industry. In brief, our range of systems and services covers the following:-

- MSE Metal Thermal Spray Solutions (include HVOF spray, PLASMA spray, ARC spray, spray and fuse, powder, wire etc.)

- MSE Laser Marking and Engraving Solutions (applicable to aluminium, steel, plastic, copper, ceramic etc.)

- MSE Laser Welding Solutions (200 watt to 400 watt source, special attachment, Jigs fixture equipment)

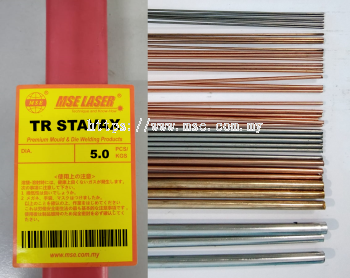

As the one-stop industrial laser sales and services hub in Malaysia, MSE also provides and supplies an extensive laser welding products and welding services to fulfill the local mould and die industry, including:

- Laser welding machine

- Laser jigs and fixture

- Laser welding accessories

- Laser welding special material/consumables

- Laser welding development

- Laser welding technique and theory training

WHAT IS THERMAL SPRAY COATING SOLUTION

Thermal spray coating is a coating process that thermally adds a functional surface to protect and also improve an engineering component in terms of its performance. In general, there are almost all types of material can be thermally sprayed with coatings. Therefore, thermal spray coatings are widely used to provide protection from corrosion, wear, heat and a variety of other applications.

US 17587

US 17587  GB 12520

GB 12520  BR 10930

BR 10930  CA 10506

CA 10506  AU 9777

AU 9777  IE 5003

IE 5003  NZ 3885

NZ 3885  IN 1359

IN 1359