The RSP series of gas burners are pre-packaged, fan assisted units designed to suit virtually all types of gas fired applications where recirculated air is utilised. The RSP can be fitted into process air ducts having air velocities of 5 to 30m/sec.

The burners can be installed in a process plant recirculation system where it is not possible to construct a combustion chamber and install a conventional type of burner assembly.

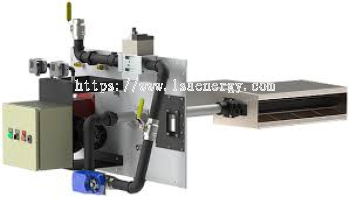

The units consist of an 'in-line PH' type combustion head mounted on a side plate so as to fire parallel to the side plate in direction of air flow. The burners are avilable in 'straight', 'T' and 'X' sections which enable the burner to be constructed to suit the appliance layout.

All air required for combustion is supplied by a combustion air fan mounted on the outside of the side plate; air is passed to the burner head via an integral air duct. Process air temperatures up to 300°C can be accepted upstream of the burner. Downstream temperatures should be limited to 600°C.

The burner systems produce a wide flame spread and a short flame; this feature means the burner is ideal for applications where chamber length is restricted.

The SP burner is simple and safe to operate. All burners are prefired and fully tested before leaving our works.

Product Name: Recirculation Side-Plate (RSP)

Type : Nozzle Mix

Capacity Range : 500, 000 to 30, 000, 000 (Btu/hr)

147 to 8785 (kW)

Turndown : 21:1 up to 100: 1

Fuels : Natural Gas, Propane, Butane

Typical Applications :

- Dry-off and curing ovens

- Incinerators

- Indirect air heating

- Textile drying

- Annealing

- Aluminium homogenizing

US 16219

US 16219  GB 11510

GB 11510  CA 9821

CA 9821  AU 9218

AU 9218  IE 3884

IE 3884  BR 2079

BR 2079  NZ 1742

NZ 1742  IN 1098

IN 1098